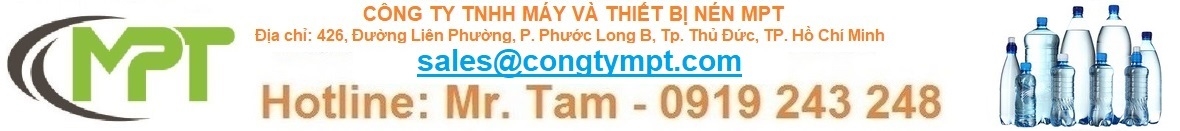

Description

A higher volumetric efficiency and alignment of the cylinders directly in the cooling-air flow are the pre-conditions for low condensation temperatures and therefor long service life of the valves. The generously dimensioned industrial components guarantee long inspection intervals and low maintenance costs. A special system for leakage testing of the whole machine during standstill (without running noises) simplifies the diagnosis during maintenance work.

Compressor:

- Type-tested safety-valves for all pressure stages

- High efficient cooling

- Microfilter at outlet

- Energy efficient IE3 motor, direct flanged

- Elastic coupling for smooth start

- Manometer for all pressure stages and oil pressure

- Oil-pressure-lubrication with oil-pressure-contorl

- Full automatic discharge

- Vibration-free assembly

- Electromagentic start discharge

Compressor unit:

- Compressor

- PLC Control

- Pressure sensor for end-pressure

- End-temperature-control

- Flexible hoses

- Ready mounted and wired on common base

Optional equipment:

- Pressure-switch at all pressure stages

- Temperatur-contorl of all pressure stages

- Compressor-heating

- Sound insulation hood

- Condensate tank for wall mounting

Technical data

| Application, medium | Stickstoff / Nitrogen / Azote |

| Max. operating pressure | 350 bar |

| Stages | 4 |

| Inlet pressure | 0,1 / 0,3 bar |

| Delivery quantity | 1200 / 1300 l/min |

| Driving power | 30 kW |

| Drive speed | 1500 rpm |

| Cylinder count | 4 |

| Operating temperature | 5 - 40 °C |

| Length | 1460 mm |

| Width | 1050 mm |

| Height | 1085 mm |

| Weight | 600 kg |

| Outlet temperature | ca. 10 °C über Eingangstemperatur |